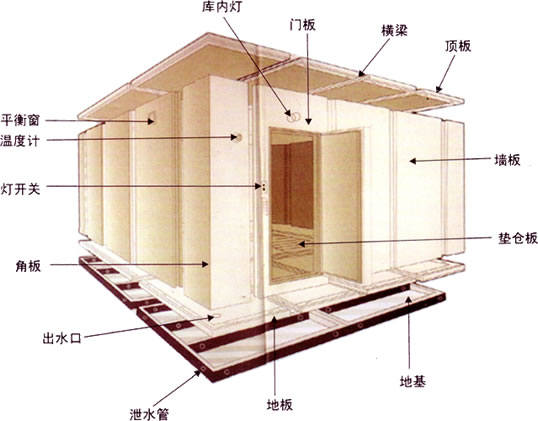

Combined cold storage

intro

Combined refrigerator specifically for seed production, storage tea, tobacco processing, food processing, meat, poultry, rabbits, eggs, ice, vegetables, ice cream, fish, shrimp and other department stores, liquor brewing, pharmaceutical and chemical products storage and research and design and manufacturing. Having a cooling, dehumidification, heating, humidification and other functions, you can maintain the accuracy of air temperature and humidity regulation.

Cold new materials

Cold storage insulation superior performance, cooling speed, long insulation properties, compared with other cold storage, saving 30-40%.

Easy assembly and disassembly: siding with internal cold snap coupling embedded parts, easy assembly and disassembly handling, installation enable time is short, cold storage construction installation cycle is 1/3 ~ 1/20, small refrigerator usually 3 to 5 days to pay to use it side of the mobile units and transport areas particularly suitable.

Cold green energy

Cold Intelligent Control System

Compared with the general cold storage system, this refrigerator has the following characteristics:

Buy large and small cold storage

:( Glass panel has cold steel, stainless steel, color steel plate), the library board with rigid polyurethane foam insulation materials and advanced technology at once, any combination of a variety of its light weight, high strength, good thermal insulation performance (the ≥ 0.024Kcai / m, h, ℃), corrosion-resistant, anti-aging (FRP immersed in the East China Sea after 15 years of aging), decay, non-toxic, mildew, can show its superiority at ultra-low temperatures.

Energy-saving insulation cold storage

Complete series: cold storage houses siding specialized production, formed a series of interchangeable, any combination of the formation of a variety of specifications of the Treasury, the user full use of existing venues and building space provided for convenience. Storage temperature are ± 5 ℃, -10 ℃ ~ -18 ℃ and -18 ℃ ~ -23 ℃ up to the following special cold -30 ℃, can meet the different needs, a combination of a variety of specifications, indoor and outdoor two types: single rooms, double rooms, suites; supporting a library: ceiling air coolers, exhaust pipe two kinds optional.

According to "Montreal Protocol", is currently in cold storage refrigeration system commonly used Freon refrigerant, the destructive effect on the ozone layer, will be banned. (For CFC refrigerants will be deactivated by 2010, developed countries have been disabled by the end of 1995; for HCFC refrigerants in developed countries no later than 2030 disabled, while the developing countries at the latest in 2040 disabled.) the company adopted new environmentally friendly refrigerants in cold storage system, launched a series of green refrigerator.

Cold air purification and deodorization

Cold storage using new electronic devices in addition to smell, high-pressure discharge ionized air to produce ozone, odor it with library component (sulfides) chemical reaction, eliminate the odor, the library effectively inhibit the growth of microorganisms and maintain inventory of food hygiene. The devices other than smell the effective rate of 95%, without manual operation, low energy consumption and long service life.

Cold supporting diversification

Cold storage insulation material varied: there are core insulation polyurethane, polystyrene and the like. Panel materials are glass, steel, color steel, stainless steel, aluminum, and other relief; refrigeration host varied: choose different brands of imported or domestic refrigeration compressors; cold diversification purposes: with a temperature preservation library 0 ℃ to 15 ℃, the low-temperature refrigerator (temperature from -28 ℃ to -18 ℃) or with one of the above two temperature dual temperature cold storage.

Cold storage dedicated microcomputer automatic control cabinet, cold storage to achieve automatic control daily operations.

Reasonable advanced optimization system configuration

Reasonable Matching cold storage refrigeration equipment systems play performance plays a vital role. After years of engineering practice, using the best match system, the refrigeration equipment to achieve the best cooling capacity and the best operating results.

1, green, odor antibacterial, energy saving, low operating costs

2, reliable, no maintenance worries, cooling speed, low noise

3, high-efficiency air-cooled or water-cooled condenser

4, choose a variety of radiator (can be divided into finned, shell and tube and plate heat exchangers, etc.)

5, refrigerant varied refrigerant (ammonia, carbon dioxide, Freon, propane, helium, etc.)

1. Inter-cooling for refrigeration or into the library after the pre-cooling required to freeze (freezing technology refers to the use of secondary) of food at room temperature, cooling or pre-cooling. Processing cycle is generally 12 ~ 24h, the product after pre-cooling temperature is generally 4 ℃.

2. The need for inter-freeze frozen foods at room temperature or by a state of rapid cooling down to -15 ℃ or 18 ℃, the processing cycle is generally 24h.

The cooling was also known as cold room temperature refrigerated room, mainly used for storage of eggs, fruits, vegetables and other foods.

Frozen Food Storage Room 4, also known as cold storage rooms, the main storage by freezing processed foods, such as frozen meat, frozen fruits and vegetables, frozen fish and so on.

5. Inter-freezer, also known as ice storage for storing artificial ice, solving problems and need ice season ice ability contradictions.